New on the E22 arsenal; the E.22 X3 is a lightweight aerodynamic aluminium wheelset.

New on the E22 arsenal; the E.22 X3 is a lightweight aerodynamic aluminium wheelset.

It is 30mm in depth for aerodynamic purposes, and lighter than carbon competitors of similar depth. The X3 handles beautifully in the cross-wind, and maintains a high quality ride at high speeds and on bumpy roads.

The X3 has a different cross section from its predecessor, the X2, which featured a traditional box-section design. With this new rim shape, we were able to increase lateral stiffness of the overall rim, with a minimal trade-off in weight.

For our lightest climbing combination, our E.22 rims are laced to the Italian-made Carbon-Ti hubs. We use premium Titanium spokes from Marwi Ti-dye and Sapim Polyax Nipples to complete the build.

Read more here.

Our E.22 wheelsets are offered in an array of premium hubs to fulfil the needs and preference of the rider.

Each E.22 wheelset is handbuilt by one of our in-house wheelbuilders. Upon purchase, our wheelbuilders will get in touch with you, to confirm the colours of your components.

Our X2 (Gen2) rims are sandblasted to create a rough finish. The surface is then hard anodised to ensure longevity. Logos are laser etched on.

There are several factors that attribute to the strength, weight and durability of our rims.

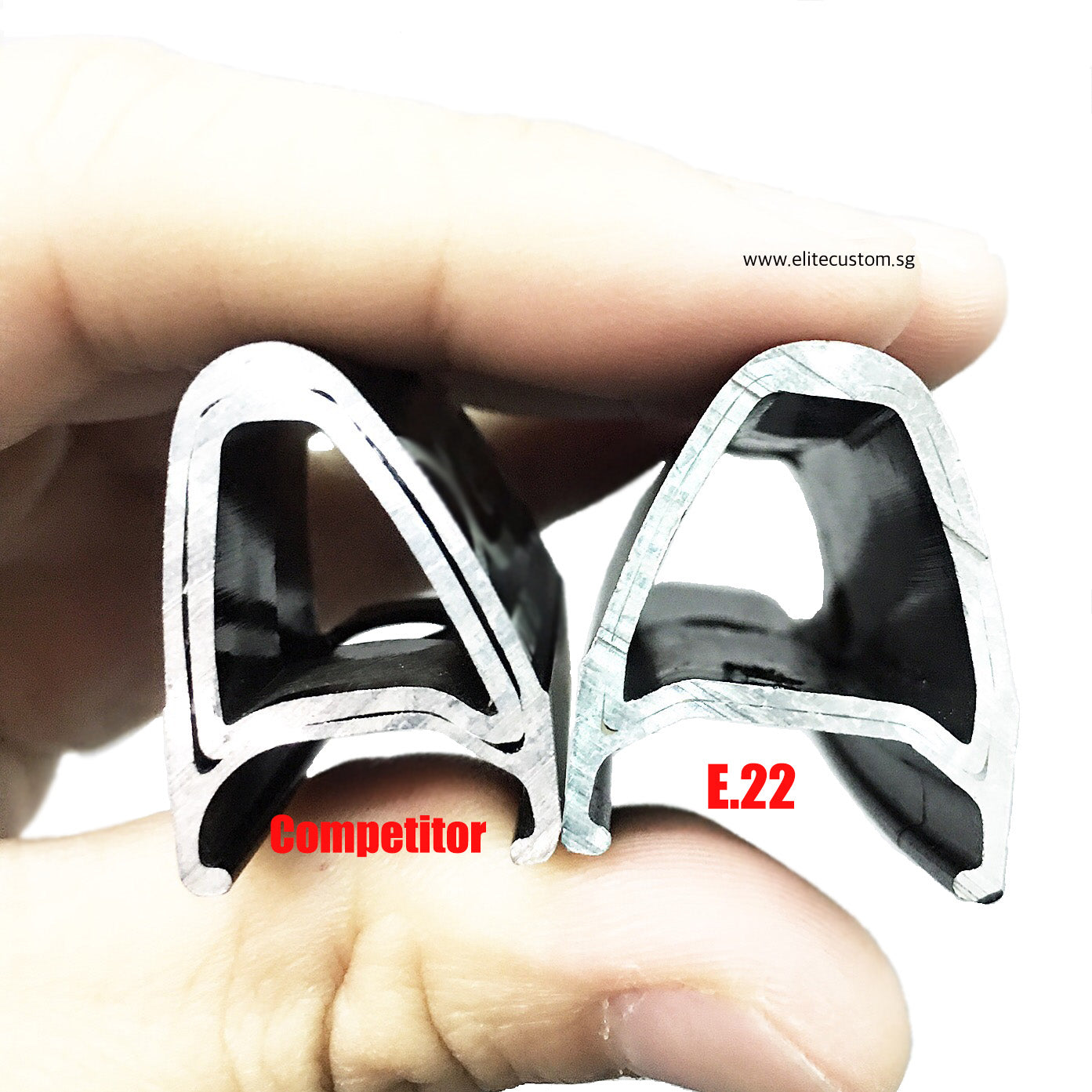

If you refer the cross sections above, there are two things you would notice about the competitor's rim.

The first is, there are voids that surround the cross section, and this runs throughout the entire joint section of the rim.

Second, the competitor's rim has walls that are thicker than the E.22. We were able to achieve unparalleled strength and weight qualities in our rims because of a unique alloy that was used in its creation. Nothing is spared, starting with the base material which is largely, high quality aluminium from Australia and proprietary processes after extrusion. The result was a material with twice the tensile strength of conventional alloys.

| Summary |

|

| Material: |

Our rims are created from a unique alloy, with high quality aluminium originating from Australia as the base material. |

| Manufacture: |

A proprietary cold working process is applied to improve strength. |

| Finishing: |

Sandblasted - Hard Anodised Black |

| Brake Wall: |

CNC - Hard Anodised, Black |

| Logo: |

Laser Etched |

Q: What is the Black brake track for?

A: Purely Aesthetic, but 100% functional. It was initially designed for track and fixed gear riders with little or no intention of utilizing the brake track. It would also appeal to those who might want a pair of road-disc or cross-disc clinchers. That said, they seem to be gaining popularity with the roadies, as the market trends towards alloy rims that are black and stealthy.

Q: Is the Black brake track ceramic?

A: No, we've worked on and tested a number of ceramic brake tracks, but they always chipped and they ultimately resulted in unwanted pulsation and rough braking. Instead, the surface of our brake track is hard anodised.

Q: Will braking remove the Black brake track?

A: Friction from braking removes material from the surface, even on the CNC-ed Silver variant. However, since only the surface is Black , the wear-and-tear is more noticeable as it turns to silver.

Q: Do I need to use special brake pads?

A: It is not absolutely necessary, but softer pads would preserve the Black coating for a slightly longer period. Pads from Swiss-Stop and Kool Stop work best in this application, whilst Shimano pads wear the brake track much quicker.

Users are also advised to use new brake pads as old brake pads would contain shards of metal that would accelerate wear-and-tear on the brake tracks. Hard braking in wet weather would also attribute to additional friction and premature wear-and-tear.

Check out the Warranty and FAQ page before purchasing.

Colour Options: